From the idea to tailor-made innovation

Engineering / OEM

Our development department is always keen to face new challenges. We develop electromechanical assemblies for laboratory application, from the first pencil sketch to series production according to your requirements.

Modern CAD System

Sadly, good ideas often fail at barriers of modern industry: customers that aim for a large-scale production are always welcome. Nevertheless, we take care of your single-piece and batch production.

Single piece and Batch production

OEM-Development

Our well-equipped workshop enables us to manufacture mechanical parts made of metal or plastic for prototypes and functional models. This saves time and money. You receive planning, documentation and production from a single source.

In-house prototype construction

To turn your ideas into reality, we use latest CAD software for efficient and detailed planning. Moreover, 3D modelling allows the visualization of the recent design and thus provides an optimal basis for regular exchange.

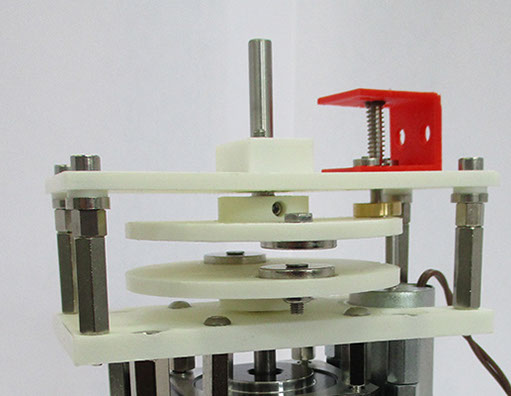

The use of 3D printing opens up completely new possibilities during the prototype development. In no time, parts can be printed to check the feasibility of mechanical concepts. In this way, not expedient ideas can be identified in an early stage and optimized before high costs result from the mechanical production of metal parts. Acquired knowledge is included in the planning in order to achieve the best possible result in this early stage.

Rapid Prototyping

We have been developing OEM assemblies as well as devices ready for serial production for more than 30 years. Thus, we are a reliable and experienced partner.

Our solutions are characterized by their high quality at a reasonable price. We design mechanical systems that suit your requirements and take care of a tailor-made casing with your corporate logo, if necessary.

A subsequent phone call or online meeting to get in personal contact and to talk about your requirements more detailed has proven its worth.

Identify your requirements

(duties and obligations)

Based on your specifications we develop solution concepts for their technical implementation. Together we decide which concept meets your requirements the most and consequently should be realized. Based on this decision we make you an offer regarding the expected costs.

Development / Construction

The chosen concept is modelled in detail using CAD software. This includes the design and calculation of mechanical axis and drives as well as the equipment with necessary sensor technology. The progress is reported regularly keeping you always up to date.

Once construction is completed successfully and no requirements remain unvoiced, we prepare the mandatory documentation in the form of production drawings and organize the assembly of a functional model. This will be handed over to you for extensive testing.

Experience has shown that during the testing, requests for additional features arise or small changes are necessary before the device is marketable. We adapt the construction based on your demands.

Functional Model

Prototype

After updating the model and the respective drawings according to your specifications, we manufacture a prototype designated for testing at your site. Assuming no modifications are required, the prototype is ready for serial production. This is not mandatory; we realize single piece production as well.

Examples for taylor-made assemblies

Lever mechanism for lifting covers of petri dishes

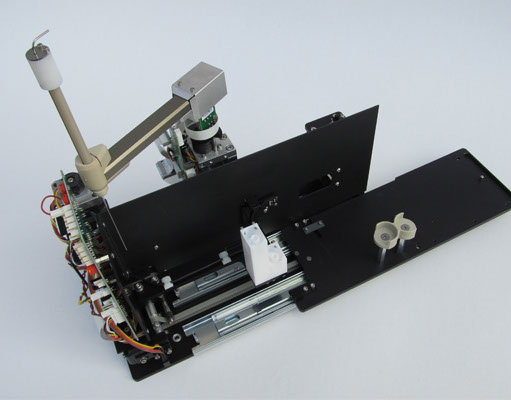

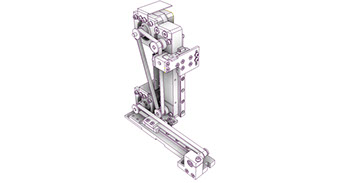

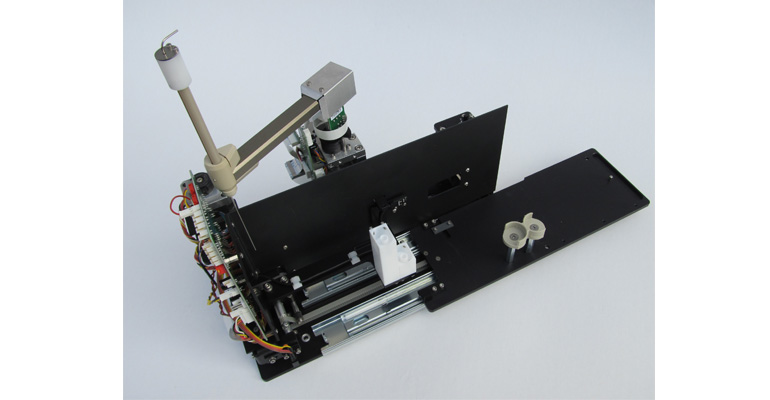

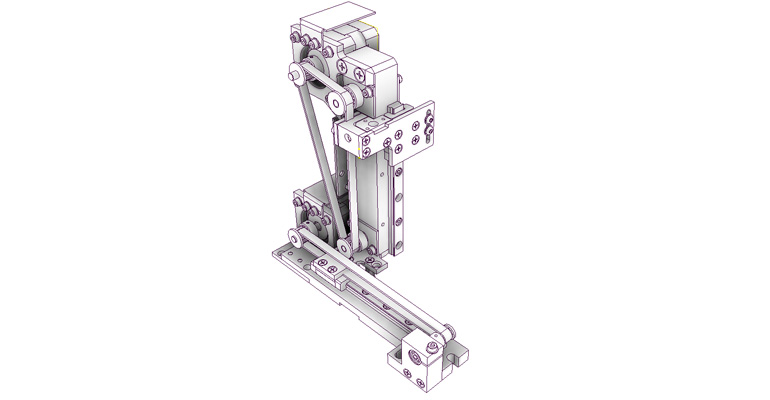

Multi-axis system for handling of tall and low microwell plates

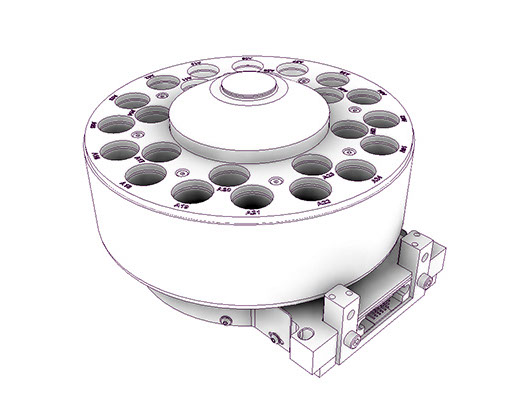

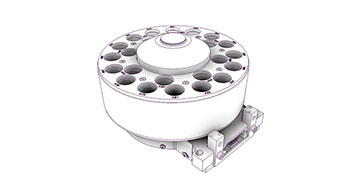

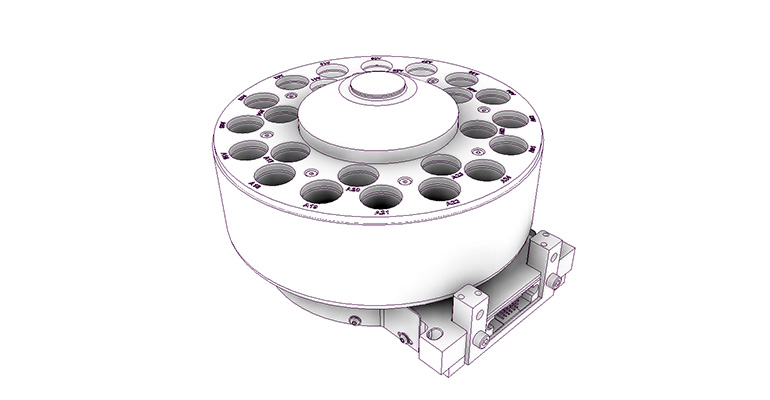

A temperature controlled carousel for up to 24 samples

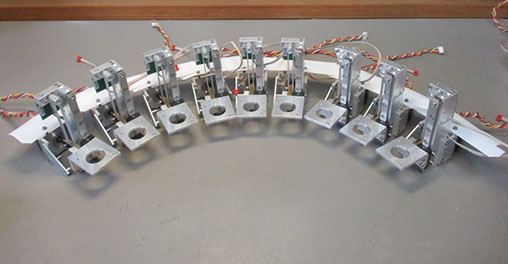

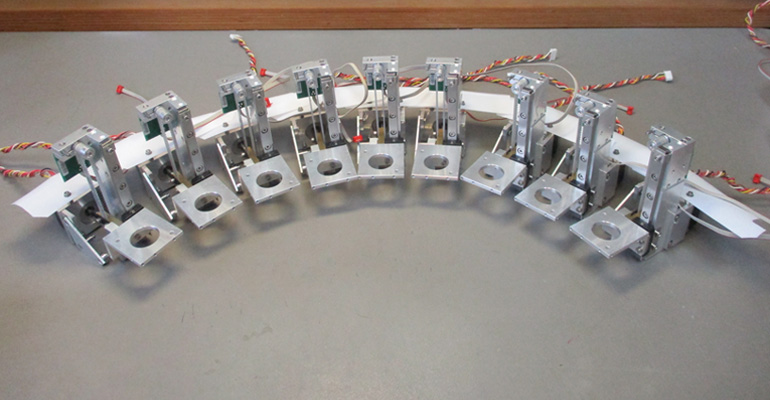

Small batch production of electromechanical assemblies

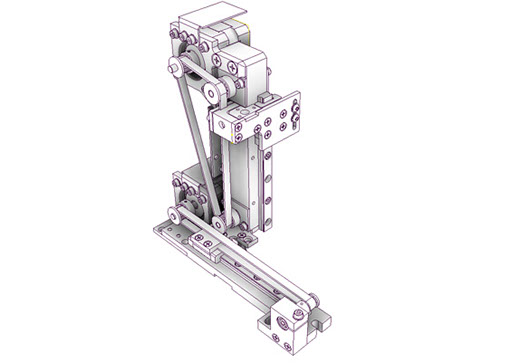

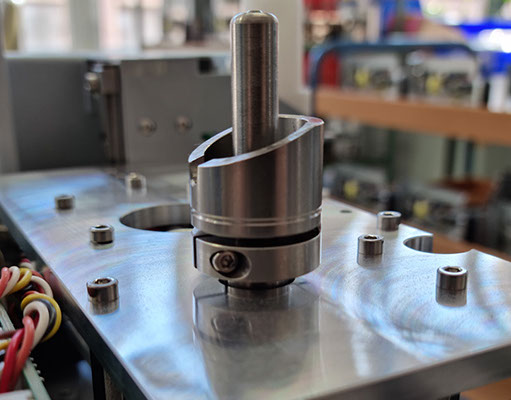

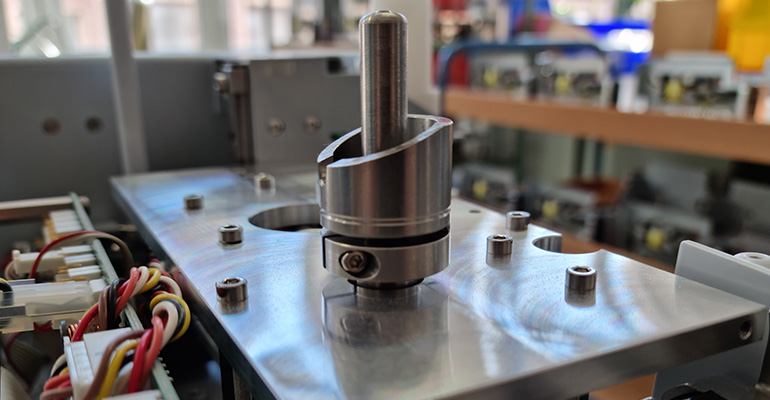

Two-axis system for automated sampling of liquids in vials sealed with septum

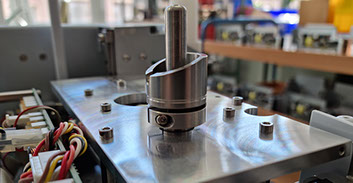

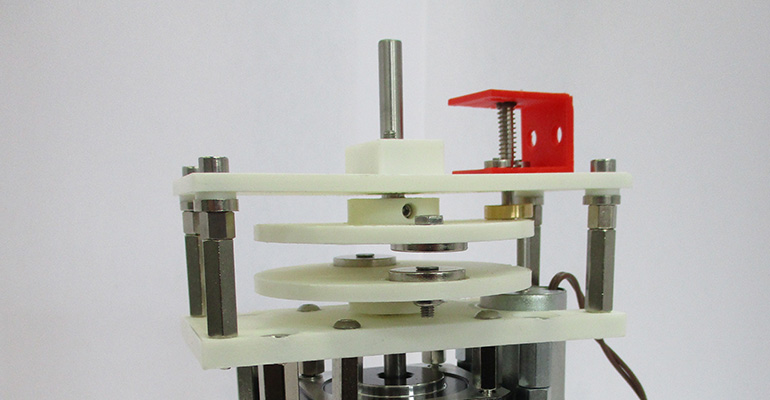

3D printed functional model of magnetic clutch for contactless transmission of torque

Drive of a sample tray for automated liquid handling

CONTACT

Bernhard-Voß-Straße 27, D-01445 Radebeul, Germany

Phone +49 351 83381-0

Fax: +49 351 83381-11